MY YEARS AT NASA/MSFC 1963—1999

SOME OF THE MORE INTERESTING

PROGRAMS/PROJECTS

THAT I WAS A PART OF, INCLUDING SOME

HISTORY NOT KNOWN BY MANY

ROCKET CITY USA

HUNTSVILLE, ALABAMA

REDSTONE ARSENAL

BY GEORGE HARSH

DEDICATED TO

JACK WAITE

GUY PERRY

JACK CONNOR

DON DONALD

RANDY HUMPHRIES

GLENN ROBINSON

CHUCK VERSCHOORE

KARL HEIMBURG

KEN HILL

CHARLEY WOOD

GORDON PLATT

GLENN EUDY

BILL EOFF

MIKE PESSIN

HUNTSVILLE, ALABAMA

NOVEMBER 2022

HARSH HISTORY— MSFC

I started at the Marshall Space Flight Center, I was an unofficial Section Chief—unofficial means that I was a Supervisor, but my job description did not list me as a Supervisor —not a problem, if fact I’m too busy working to read my job description!! And I’m not sure that I knew I even had a job description until post Apollo!!

I was in the Test Laboratory, Components Division, Environmental Branch, Environmental Test Section, and my Engineers were: Don Donald, Randy Humphries, and Glenn Robinson. They were all OUTSTANDING, Personally and as Engineers, each in their own way !! I was blessed to be working with them; I already knew Don, and BTW, Randy would later be Dr. William R. Humphries, PHD.!! And a Laboratory Director!!! Each Engineer had 2 Mechanical Technicians assigned to them. All of the Technicians were older than us and I thought that all were basically just as intelligent as me, and maybe more!! The difference was that I had an Engineering Degree.

Note: None of the Technicians or Engineers worked FOR Me—they all work WITH me !!

We had 4 test programs.

1. Don Donald, Test Engineer—Hot firing tests of the Auxiliary Propulsion System (APS) Module for the Saturn V’s S-IVB Stage. This system used Toxic, Storable Propellants. We had never worked with Hydrazine & Nitrogen Tetroxide, but we completed Testing of the Module with no problems. Test Lab personnel were always responsible for our own Safety. And with this program, we worked on grating with water flowing underneath to wash away any spills or drops of the toxic propellants. This water flowed to a holding pond, where we neutralized the contents before draining the pond about once a month.

If we had a major spill, there were telephone numbers to call to evacuate the 3 adjacent Laboratory’s of all personnel!! After the Program was completed, I used to brag that I could have given almost 1/2 of MSFC the day off!! ;-0)

Post Apollo, we began preliminary work for a SKYLAB APS Module Test Program, and were just a few weeks away from the initial hot firing of the Module in a Vacuum Chamber, when we received word that the SKYLAB APS Module had been canceled!!

The Module had thrusters in every axis of the SKYLAB, and therefore could maintain the Orbiting Altitude, and thereby it was a “ploy” by NASA to turn SKYLAB into a “Mini-Space Station”!! This, I did not know at the time. A few years later, I read ( TIME Magazine & WSJ ) that when the Nixon Administration figured that out, they knew that NASA would want more & more funds for this Space Station—so its APS was canceled as these funds would probably be needed for the Vietnam War!!!

2. Glenn Robinson, Test Engineer—Testing to support the development of the insulation inside the Saturn V’s S-II Stage by loading an insulated Test tank with Liquid Hydrogen to determine the insulation’s thermal conductivity.

3. Don Donald & Glenn Robinson, Test Engineers—Hot firing tests of a Cluster (5) of small engines into a Large Water tank simulating the Launch of the Launch Vehicle that would follow the Saturn V—The NOVA. The NOVA Vehicle was so Huge that it would have to be launched from a “Texas Tower” off shore from KSC, as if there was a catastrophe explosion at Launch, the over-pressure wave would flatten many structures on shore!! Especially in Titusville, FL !!! 3 After about 10 Test Firings, this program was stopped as I think that MSFC knew that there would be no launch vehicle developed immediately after the Saturn V.

4. Randy Humphries, Test Engineer—Testing of a new insulation, Super Insulation, as discussed following in this publication. It was for Long Term Storage of cryogenics ON THE MOON—or MARS !!

These last 2 test programs are great examples of the von Braun Team ALWAYS PLANNING AHEAD, as they were for future programs, and were not required for the Apollo Program.

THE SUPER INSULATION TEST PROGRAM

Randy Humphries, Test Engineer

“Super Insulation” (S I) is multi-layers of Aluminum foil and Mylar. Like the blankets runners get after finishing a marathon.

One of the Design Laboratories had insulated a 9 ft. Diameter x 20 ft. long tank with Super Insulation, and Requested Test Laboratory to test it (filling it with Liquid Hydrogen) in a vacuum chamber simulating the vacuum & coldness of outer Space. The test objective was to determine the thermal conductivity of Super Insulation. Since we did not have a vacuum facility, we built one!!! SIDE-BAR—I’ll tell you now, that it is against the Law, to build a Facility without it being in MSFC’s C of F, Construction of Facilities, Budget!!! (I’ll come back to that later ). Hey!! C of F is a Long Process and we don’t have time for that!! We’re Going to the Moon before 1970!!! I never heard of C of F until post-Apollo!!

So, here’s what we did: Test Lab could do ANYTHING except pour concrete. i. e. we can Design, fabricate, install, mechanical, electrical etc. etc.

The Facilities Office pours concrete, and with numerous Test Facilities being built, they had personnel assigned to Test Lab. So we give them our drawings to get the concrete poured. These drawings for the foundation are entitled: Equipment Pad!! That’s true, however, our “equipment” is a four story Test Stand ( Designed by Test Lab ), a 20 ft. diameter x 30 ft. high stainless steel vacuum chamber ( Designed by Test Lab ), a number of vacuum pumps, and cold walls (liquid nitrogen) inside the Chamber, and associated Test Stand support Equipment !!! And, AND!! a Liquid Helium Refrigerator to supply LHe to the cold wall to help pump the chamber to ultra low vacuum. Like 10 to the minus 6 or 7 mmHg. Which was AMAZING for a chamber not in a building !! This Facility was outside because of safety concerns with the large amounts of Liquid Hydrogen. And we did not have Funding to enclose it in a “Liquid Hydrogen Safe Building”. Of Course, the Apollo Moon Program paid for everything, and I assumed that this program was for JSC, and we’re working overtime like crazy!! Then one day I asked the Test Requester where was JSC using Super Insulation for the Apollo Program ? He said, NOWHERE !!! It’s For Long Term Storage of Cryogenics ON THE MOON !! This is one of many Examples of the “von Braun Team” ALWAYS PLANNING AHEAD!!

OK, back to breaking the Law—-I had never heard of a C of F Budget until after Apollo was completed, and a Facilities Headquarters Team came to MSFC to see if who, if any, had Built Unappropriated Facilities ??! The main way that’s done is to check that all Facilities have a Building number, like 4748. And we didn’t for the S I Test stand & GOTCHA!! It would have been interesting to be with them as they searched MSFC for Unauthorized/Unappropriated Facilities!! So, they “Caught” Test Lab, but no one even got disciplined— it would have started with me & the Test Engineer, & included my Branch Chief, & Division Chief, and the Facilities Office personnel assigned to Test Lab. I never asked how high up was this practice known. And we were not the only ones, as Equipment Pads were common practice during Apollo & before!! So with the NUMBER of Guilty personnel involved, Headquarters essentially said Bad Boys & NO MORE!!

Interesting, the practice that followed was to snuggle the new Facility close to an existing Facility & call it a Facility Modification !! Therefore, not requiring a C of F !! A great example is the SMALL, OLD, 1 STORY Shuttle-C Building, that I was in for 3-4 years, is now dwarfed by a New multi- Story Research Building!!!

I don’t recall how the S I Test Program ended—-the Thermal Design Guys took the data & began their calculations. Of course it would be very interesting to know if our test program helped design the thermal blankets used by runners at the end of long races. Or, when we need long term storage of cryogenics on the Moon, or MARS!!!

At one time it appeared that Test Laboratory would need a number of vacuum chambers to support the potential test requests. Therefore, Karl Heimburg, the Test Laboratory Director had his “Technical Staff”, Fritz Kramer, prepare a presentation to Dr. von Braun on a potential Test Laboratory “Vacuum Farm” !! Mr. Kramer was a short, dapper, highly intelligent person, always immaculately dressed in a suit & tie, with a full head of salt & pepper hair, combed back. I never saw him without His suit coat on. He visited me to learn of any especial problems with a vacuum chamber being outside—exposed to the elements. During the dry run presentation to Mr. Heimburg, Mr. Kramer read his presentation—of course he WOULD NEVER do that in presenting to Dr. von Braun. I was lucky & attended the dry run in Mr. Heimburg’s Conference Room. One problem we had with an outside chamber was with the 20’ diameter Dome off of the chamber, a few bumble bees and wasps got in the chamber. So when Mr. Kramer said: “…….with the Birds and The Bees and the pollen from the trees…” Mr. Heimburg interrupted with: WHO WROTE THAT BULL ?!!? My immediate thought was that he thought that I had, and had talked Mr. Kramer into saying that & Mr. Heimburg was going to “breathe fire” on me !!! He was noted for his fiery short temper !!!! My next thought was: I’m going to see some of the famous Heimburg Fire directed at poor Mr. Kramer !!! Nope, didn’t happen either, as Mr. Kramer very calmly looked up and said: “ Why I did.” Mr. Heimburg did a bit of a double take and said: “ It’s very nice !” In hind sight, I wished that somehow I’d gotten to attend the von Braun meeting. BTW—- the Vacuum Farm never materialized.

THE SKYLAB MAN-RATED ALTITUDE CHAMBER AT MSFC

George Harsh, Test Engineer

FYI: I know that now-days it’s Human-Rated or Crewed! However, back then it’s Man-Rated, or Manned.

During the early development of SKYLAB, Test Division received a request to conduct Crew Comfort Tests at 5 psia to provide data for the design of the heating, ventilation, air conditioning (HVAC) System. For these tests, we needed a Man-Rated Altitude Chamber, which none existed at MSFC!!

I had read in the Magazine, NAVAL AVIATION NEWS, about the Naval Aerospace Medical Institute at Pensacola, FL. I picked a name from the article, a Commander, called him, and Yes!, they had an excess Chamber at the Jacksonville, FL, Naval Air Station ! So I traveled to JAXNAS & checked out the old, WW II, Training Chamber & it was perfect for our needs ! All MSFC had to do was pay for its removal from a building, and the shipping to Huntsville. Our Lab’s Administrative Officer was an ex Navy Chief so he handled all of that for me!

We installed our Chamber in a rather new Building, in a clean Hi-Bay Area, & started stripping the chamber and then sand blasted the inside.

Next, we painted the inside with “Skylab Paint” @ $80.00 per Gallon, a significant price back then (1971) !! I did not want ANY PART OF THE CHAMBER TO BE SOMETHING TO BE USED TO SHUT US DOWN !! Meanwhile, JSC was making a few forays in that area, like the 4 Test Subjects Will pre-breathe 100% Oxygen for 2 hours before making the one hour test “flight”. We agreed, no problem. Also, you must have a M. D. present for each “flight”. Also, no problem, as little did they know that Dr. Tulio Figarola, a young M. D. in our MSFC Medical Center, was a Big-Time “SPACE-BUFF” and enthusiastically joined our Test Team!! Note: For most Altitude Training Chambers a M. D. is not at the chamber, but on-call nearby. In each 1 hour test “Flight” the 4 test subjects sat at a table, with their oxygen masks on, and played cards, and every 15 minutes voted by paper ballot as to their comfort level, as the Temperature, etc. etc was varied. I had a list of 20 employees who had volunteered to be test subjects, and had passed the physical examinations.

Next, MSFC asked JSC to CERTIFY our Test Team as Manned Altitude Chamber Operators. Their reply was NO!! Manned Testing is conducted at JSC, and definitely not at MSFC!!! I could care less, as I just called my contact, Commander Damato, at Pensacola NAS, and he immediately said that he would set up, just for us, a 2-week course to Certify our Test Team as Man-Rated Altitude Chamber Operators !!! Traveling to Pensacola NAS was Dr. Tulio Figarola, 2 Test Engineers, 2 Lead Foremen, ( 1 Mechanical, 1 Electrical ), and me, The Test Engineer for these tests. Our 2 Technicians were not approved physically by the Flight Surgeon to make a Flight in the Altitude Chamber. We other 4 were cleared & made a Flight with several Navy enlisted men. Their regular Flights were to 25,000 ft. ( 5 psia ), and each person wears a mask breathing Oxygen. Everyone is paired up as 2 man teams, and each will experience hypoxia ( a Lack of Oxygen ) by removing their mask. After 4 minutes without Oxygen, your teammate tells you to put on your mask, and if you don’t do that, he puts on the mask for you. Hypoxia does not affect one the same way every time. I clearly had Tunnel Vision, and was subtracting 3 from 100—writing the results on paper. I immediately made a mistake: 91-3 =89 !! I remember getting to 58 & writing it twice, but nothing after that!! My paper showed that I wrote 10 more numbers, each in descending oder, and when I wrote 18 twice and 15 four times!! “PUT ON YOUR MASK !!” And I did with no help! And the 4 minutes was about up. I still have that piece of paper, but “filled” it for safe keeping, & now CANNOT FIND IT!! 🙁

So we returned to Huntsville with ALL Six carrying a card stating Certified Manned Altitude Chamber Operator. Then, GUESS WHAT ?, JSC said come on down and we will Certify the MSFC TEAM! So we did & they did. I could say…….??!!?……using words like amateurish & child’s play, but I won’t. Our test team spent 3 days at JSC, making a “flight” with masks off at 25,000 feet altitude, etc. etc. I did not get Tunnel Vision—in fact, I didn’t know that I had Hypoxia until I was told to put on my mask!! …put on my mask !! Then, after our time at 25,000 ft., we climbed, as planned & explained to us by JSC, to 45,000 ft. to experience 2 phenomenons associated with that! Actually, we didn’t quite make 45K, as 1 test subject raised his hand indicating severe intestinal pain from expanding gas, so return to ground level!! BTW: I was close to hand raising !!

Years later, I thought: WHAT WAS THAT ALL ABOUT ?! Our Test Program was at 25,000 ft. & no higher. Strongly Suspect a “Welcome to the Big Leagues, Boys!!” And that’s OK !! No Problem !! And Why Thank You—We Learned a Bit. :-0)

During these times, a JSC Navy Flight Surgeon was calling our Deputy Lab Director, Jim Kingsbury, to “discuss” our test program—Like Shut it Down !!! He used “salty Naval language” that was somewhat embarrassing to Jim who was a Lay Methodist Minister. Jim easily handled that, and would never complain, but Marshall Management found out, and the JSC guy was given 2-3 other names to call!!

In a HUGE—HUGE !!! Step towards being Operational, The “Finishing Touches” ( Control Panels, Masks, Breathing Stations, etc. ) for Our Chamber were completed by a “Do it all” Engineer/Technician from Hill Air Force Base, Utah. One of their missions is to install Altitude Training Chambers World Wide. So our Chamber essentially looked like all other Chambers !! Thanks to Guy Perry, our Branch Chief, and an Ex Air Force Jet Pilot, for this!!

As a last ditch effort to shut us down, JSC sent up a retired Lt. Col. with significant Chamber experience to “shake us down” and shut us down !!! However, they made a CRUCIAL MISTAKE—they sent a no nonsense Guy with no JSC—MSFC axe to grind !!! We are EX HAZARDOUS PROPULSION TEST ENGINEERS AND TECHNICIANS ( with significant testing experience ) AND WE HAVE PROCEDURES FOR EVERYTHING ( INCLUDING EMERGENCIES ) & WE USE THEM !!! AND WE’VE ALWAYS BEEN RESPONSIBLE FOR OUR SAFETY and Quality Control!! We conducted an Unmanned “Flight” for the Colonel, and he gave us 3 emergencies during the “Flight” that we handled easily!!! Then he made 3 minor suggestions that I incorporated immediately, and he returned to JSC & told them what he found, and What They Did Not Want to Hear !! i. e. Those MSFC Guys know what they are doing !! BTW: At the start of the “Flight”, I informed the Colonel that if this was a manned “Flight”, Dr. Figarola, M. D., from the MSFC Medical Center, would be sitting beside me, with a headset on, looking at the test subjects through a window that was across the width of the chamber. And I also showed the Colonel our Medical Room, adjacent to the Chamber, that I had stocked with supplies and equipment as Recommended by Dr. Figarola. I suspect that not many other Chambers have an adjacent Medical Room!

This “contest” finally elevated to the Center Directors Level— WHAT ??!! “YOU CANNOT BE SERIOUS !?!?” AMAZING—I DIDN’T KNOW WE WERE THAT IMPORTANT!!! Maybe I should get my own Autograph !!? :-0) and we received the word that our test program was approved, ( and ONLY THIS PROGRAM—NO OTHERS !!! ) but NO TESTING until an approval fax came that afternoon. Making The First Flight was Duane, the Hill Air Force Guy and me. I, of course, needed to be in the First “Flight”, as my thought process has always been: If I’m not in the First “Flight”, etc., etc. how can I ask others to “FLY” etc. etc. As we were pre-breathing oxygen and waiting on the fax, Karl Heimburg, our Laboratory Director, got fed up and showed some of that “famous Heimburg Fire” and said: “RUN THAT TEST—NOW !!!!” And even though Mr. Heimburg was a Propulsion “Smoke & Fire” Guy, He came to the Chamber and looked in through one of the small observation windows, as I gave him a Thumbs-Up !! The fax from JSC came in later that afternoon after the “Flight” was completed!!

We completed the 30 “Flights” Test Program, and I don’t recall that any Skylab Astronauts ever complained about Crew Comfort!! Post Tests, The Chamber was placed on a Government Excess List & picked up by the The State of Alabama, and sent to Anniston, AL, where, I heard, they were growing flowers and plants in it !!!! ( & not at altitude!! )

Note: For additional interesting information, read the Epilogue.

SELECTING THE CONTRACTOR FOR THE SHUTTLE’S SRM CHALLENGER —“A Tragedy Steeped in History”

(Some of the following is History not known to many)

There were 4 Companies that submitted proposals to develop and manufacture the Solid Rocket Motor (SRM) for the Space Shuttle Program. I was on the Technical Test Team of the Source Evaluation Board (SEB ) that evaluated each proposal. Jack Connor, my Test Lab Division Chief, was my Team Leader, and probably chose me because we both had solid propellant experience, working on the Army’s Pershing Missile.

My first knowledge of the Space Shuttle was when Jack explained to me its configuration, and I immediately said: Humans do not “ride” solids, not because it cannot be shut down IF something happens, but because it cannot be cutoff/ shut down WHEN something happens !!! He explained to me that for non-technical reasons, that if there was to be a Space Shuttle, part of its propulsion system would be Solid Propellant Motors!!

The ambience in the team was that Thiokol would win the SRM Contract as they were the “BIG-BOY in the Field of Solid Rocket Motors.” However, we treated all bids the same, & Thiokol won the contract. Much later I discovered that Thiokol was #4 Technically, but #1 in cost!

Very interesting, Thiokol’s proposed Qualification Test Program was VERY Anemic at best and TOTALLY Unacceptable at worst !! On our Team was Jack Bissinger, an Engineer that Jack C. & I had worked with years before at the Army Missile Command, & was now a recognized expert for Development & Qualification Testing, Especially for Solid Rocket Motors.

So, with the contract awarded & the SEB disbanded, we 3 continued on & developed a Minimum SRM Qualification Test Program, and sent it to the MSFC Shuttle Program Office recommending a contract modification! Our Proposal was swept off the table—-Can’t Afford it!! We found that unacceptable, and Jack Bissinger wrote a memo to the Shuttle Program Office, Clearly justifying the Test Program. He received a “very nice” reply from 1 of the Program Managers stating the budget constraints, etc. etc. Jack did not like that, so he sent his same memo to the next highest level in the Shuttle Program Office. That memo was never answered!! Whether or not our Test Program would have affected the Challenger Launch is unknown, however, the Lowest Temperature that the SRM’s were Qualified to Launch at would have been established!! I clearly remember thinking that since Utah has cold winters, at least 1 & maybe 2 SRM’s would be fired at cold temperatures. NOTE !!! Not if a “Tent” is placed over the SRM, and it is kept in a Warm Environment!!!! Obviously, Conducting a sufficient number of firings to qualify a SMALL SRM —-like a shoulder fired weapon—- is “easy”. Doing a similar program for the Huge, Massive, 3 Million pounds of thrust SRM is not.

During the SRM Design/Development, and early Flight Operations, the ‘Word’ around MSFC was that “ Thiokol Ran the Show” as they had much more SRM Experience than the MSFC Shuttle personnel. Remember, the von Braun Team were basically Liquid Propulsion people!

So, times change, people retire, etc. and as new MSFC personnel moved into the SRM area, some had SRM experience and begin to assert their authority over the contractor. As they should. This, of course, reached its climax with the famous MSFC/Thiokol Telecom on the night before the Challenger launch, and is well covered in the Rogers Presidential Commission Report. Some highlights are as follows. The Thiokol Engineers stated that it was too cold to launch !! When asked, the Engineers stated that the minimum launch temperature was 53 degrees F as that was the lowest launch temperature to date ( the previous launch in January 1986 ) and therefore the SRM was not certified to launch below that temperature !!! One or two of the MSFC Managers went ballistic !!! The temperature the morning of Challenger Launch was around 28 degrees, and it is appalling that a Minimum Temperature for Launch had never been established !!! Hmmmm? Don’t I remember a SEB Technical Team trying to establish that, and even provided a “bare-bones” Qualification Test Program!!

The Telecom ended with Thiokol recommending Launch and MSFC Managers directed Thiokol to put their recommendation to Launch in writing via a FAX.

The MSFC rationale for not informing JSC of the MSFC/ Thiokol Telecom was that it was CLEARLY A LEVEL III (MSFC ) PROBLEM and did not have to be Elevated to Level II (JSC ) !!!! And apparently not shared with KSC!

An Unofficial MSFC Shuttle Groundrule was : “Never raise THE LONG POLE IN THE TENT to scrub or delay a Shuttle Launch” This, of course, was never written, rarely spoken, but understood by MSFC Shuttle personnel, and apparently not discovered by the Rogers Commission.

I’ve heard, & I think also read in TIME Magazine, that the Shuttle Program was playing “Russian Roulette” with the SRM’s !! That is, in the Post Flight Data reviews, it would be reported that examination of the o-rings revealed only a “small” amount of o-ring erosion/charr which was determined to be acceptable, so another flight would be approved. Astronauts, and/or representatives from the Astronaut Office attended these Post Flight Data Reviews.

“CAPE MARSHALL” —TEST STAND 116

In the Marshall Space Flight Center’s East Test Area in the 1970’s, hot firing tests were conducted on a 6.4% model of the Space Shuttle and its Kennedy Space Center (KSC) Launch Platform. The test objective was to determine how to suppress the acoustical energy from the Shuttle’s Propulsion Systems, ( Liquids & Solids ) using large amounts of water.

One of the early tests was to be viewed by the Deputy Director of KSC and 2 of his Engineers.

The older Technicians will always tell you that, “If ‘Company’ is coming, get ready, as something ‘Interesting’ will happen!!” And yes indeed, upon ignition of the Solid Rocket Motors, one of the motor’s headend ( like a Dome) blew out, thereby destroying its connection to the Test Stand !! This resulted in the First & Last Rocket “Launch” from Marshall’s Test Area !! The motor “danced” out onto the launch platform and rose majestically into the late afternoon sky !! It was headed towards downtown Huntsville !! However, since it was burning from both ends, and doing loops, I knew that it would not go far. It went less than a mile and fell harmlessly in some pine trees, having reached an altitude of about 400 feet. The other motor fell into the Test Stand, broke up, and burned out.

I told the Test Engineer, Don Donald, over the intercom system, that I thought I heard one of the KSC Guys say, “Nice Launch Marshall”!!

After the Test Stand was secured and the “Dust settled” an Investigation Board was established to determine what happened and why. The Solid Rocket Motors had been obtained from a Government Surplus List, and Lucky for MSFC ( & me !! ) each motor had its AS BUILT manufacturing drawings. Examination of those drawings revealed a defect during manufacturing that caused the motor’s headend to blow out upon ignition —-and thereby leave the Test Stand. Before the next firing an additional tie down for the SRM’s was installed and the Test Program successfully concluded, and provided data to design the sound suppression & cooling water at the KSC Launch Pads.

Note: I had been out of the Test Division for some months and was asked by Jack Connor, the Division Chief, to return as a Section Chief—-the Section only had 2 test programs, the Acoustic Model & the 40K Engine Program—both supporting the Space Shuttle at Test Stand 116! The section had a Personnel Problem that was worsening. Jack explained that to me saying: “1. I know that you can fix the problem, and 2. I don’t know what you got, but you got it!” I accepted his offer.

As the Test Engineer, Don Donald and long time friend, was showing me the Acoustic Model, I asked, somewhat jokingly, but also Serious: Where are the log chains to be wrapped around each solid motor, not to keep it in the Test Stand IF something happens, but to keep it in the Test Stand WHEN somethinghappens !!! His answer was Very Interesting: He said that there had been a meeting on that very subject 2 weeks before and the test requesters said: No!!— any restraints added to the model will result in an “Unclean Acoustic Model” with the test data being flawed!!! After the “launch”, a restraint enclosure (mentioned above, but not a Log chain!! ) was installed for each motor, and the data was not affected!

Also Note: The firing was scheduled for 5:00 p. m. At 3:30, Don Donald called me to the Test Stand, and explained that the chamber pressure transducer on the 2nd motor to be mounted in the Test Stand had failed a final checkout, and needed to be replaced. It required a Special torque wrench to tighten it to specification, and that wrench was at the Thiokol Plant across the Arsenal. To drive at high speed to Thiokol & back would delay the firing Significantly. Don asked me what did I want to do ? I suggested that our Lead Mechanical Technician, Ernst Esch, who had removed the faulty transducer, install the replacement one to the torque that the failed one was at before he removed it. I asked Don and Esch if that made sense? They agreed. NOTE : Them agreeing in no way relieves ME of being responsible !! Also, if this, in any way, would be a Safety Issue, I would have delayed the firing !! From my early days, “trained” by Technicians in the Army Test Lab: SAFETY FIRST !!! And I’m like that, especially being raised on a Farm !! Of course if either one had said no, or expressed a doubt, then I would have delayed the firing. And I would never take even a slight risk just to fire on-time, ‘Company’ attending or not attending!! My experience in the Army Test Laboratory and at MSFC was that we RARELY USED TORQUE WRENCHES. The Technicians tighten a nut as tight as possible & then a bit more !! So the firing was conducted at about 5:03 p. m. with the results as described above. About an hour after the Stand was secured, I asked Don: Which Motor failed first? He gave me a Big Grin and said: The Other One!!

The day after our “Launch”, the Test Laboratory Director and I were being interviewed at the Test Stand, by a local TV Reporter, and the first question asked was a “what if.” “What if that container of CTF ( Chlorinetrifluoride ) in the Test Stand had ruptured and let loose a large cloud of HIGHLY TOXIC vapors ?” I quickly thought of what I would say if my Lab Director turned to me—-i. e. the wind was blowing to the SW ( away from any personnel, and Buildings) and the cloud would dissipate before harmlessly exiting the Arsenal, across the Tennessee River. The Lab Director never hesitated and spoke for about 4-5 minutes. When he was through, I had No Idea what He said, But It Was Beautiful !!! The TV Reporter said Thank You and moved on!!! That question had to be a call-in to the TV Station from someone with inside knowledge of Test Stand 116!! Tracing the “insider” was not pursued.

THIS launch and several incidents with the 40K Engine program caused Earl Choate, an Instrumentation Engineer at T. S. 116, to write the following poem, ODE TO 116!!

ODE TO 116

KEEP YOUR EYE WIDE OPEN AND YOUR EARS TUNE KEEN

IF YOU PLAN TO VENTURE NEAR 116.

A SPIRIT LIVES THERE, PERHAPS AN INDIAN CHIEF,

WITH HIS MIND SET FIRM ON DEALING OUT GRIEF.

WITH HIS C. T. F. OR (C. F. M.) YOUR LIFE MAY BE AT THE OLD CHIEF’S WHIM.

THE BASEMENT LEAKS, THE HYDROGEN TOO,

AND FIRE BALLS BURN YOUR WIRES CLEAN THRU.

THE LIGHTNING STREAKS, THE TRANSDUCERS FAIL.

YOU’LL NEED TO WAIT, FOR MORE IN THE MAIL.

THE SEQUENCER SKIPPED THE WHOLE DARN TEST HYDROGEN EMBRITTLEMENT RUINS THE REST.

THERE NEVER WAS NOTHING LIKE 116

WITH HYDROGEN AND OXYGEN THAT BURN SO CLEAN AND A PHANTOM SPIRIT THAT LURKS IN THE NIGHT

SETTING SOLID ROCKET MOTORS ON UNSCHEDULED FLIGHT.

IF YOU PLAN TO GO NEAR 116

KEEP YOUR EYES WIDE OPEN

AND YOUR EARS TUNED KEEN.

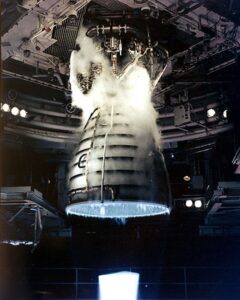

TEST STAND 116–40K ENGINE

GEORGE—FOOD DELIVERY BOY!!!

There were 2 programs supporting the Space Shuttle at T S 116–the Acoustic Model ( covered elsewhere in this publication ), and the 40 K ( 40,000 lbs. Thrust ) engine tests of the Narloy-Z Combustion Chamber Liner for the Space Shuttle Main Engine ( SSME ). Typical for the Shuttle, DUE TO LIMITED FUNDS, there was only 1 liner, so the Rocketdyne Engineer had the redline cutoff values set SO TIGHT, to protect the Liner, that it was almost impossible to conduct a test without an early cutoff !! Note: If this had been during Apollo, with Plenty of $$$, there probably would have been our test article, and 2–3 test articles at Rocketdyne, West Coast!! The Test Engineer was Lamar Thompson, an Outstanding Test Engineer, however, He always scheduled a test at 1:30 p. m., and T-0 would usually be closer to 5:30 p. m. With an early cutoff!! No matter what caused the cutoff, it always took hours to recycle for another attempt, so LONG Hours were typical for the 40 K test program. During one early cutoff, I’m “hanging around ”, trying to stay out of the way, 🙂 , and I asked Lamar if there was anything that I could help with? He said, “Are You Serious?” The way he said it made me hesitant a second and I said, Well, yeah, I guess so. :-). Lamar said, we’re starving, you could go get us something to eat. McDonalds suited everyone, so I got their orders ( about 16 ) and money, drove our Government truck to McDonalds, on the Parkway, returned, gave each their food and change. And I did that twice—the 2nd time, I gave everyone their correct change & had $0.31 left over, Wow!! Big Money!!! A year or so later, Lamar told me that that had impressed some of our crew who didn’t know me very well, as they didn’t believe that I would do that!! Hey!!

What else am I doing!!? “RESPOND AS REQUIRED” Post Apollo that’s what some “Researchers” said was the success of the von Braun Team!!

Note: During development, the SSME had numerous problems, but the Liner was never a problem there or in any flight !! This of course was due to the great testing By Lamar and his test crew!!

SHUTTLE MAIN PROPULSION SYSTEM (MPS) CHIEF ENGINEERS OFFICE

The Shuttle MPS essentially is from the Oxygen Tank’s Vent Valve at the top of the ET to the SSME’s Nozzle Exit, and “everything” in between. The ET and SSME are MSFC Projects, with Martin Marietta and Rocketdyne the Contractors. The Orbiter, with the MPS propellant feed lines in its aft end, is a JSC Project with Rockwell as the Contractor.

Someone at NASA Headquarters in Washington realized that there was no Office to overall coordinate the Main Propulsion System and integrate the 3 Projects noted above. Therefore, NASA HQS established a MPS Chief Engineers Office, and over some Objections, stated that it would be at MSFC, with MSFC’s Charles Wood as the Chief Engineer. The office had 6-7 Engineers, each with a specialty. I was fortunate to be selected by Charley as the Test Guy.

So our office went to work getting educated on the Orbiter part of the MPS and writing Technical Memos to JSC. We need to look into this, we need to do that, with Technical Justifications. JSC IGNORED Charley’s memos!! I suspect that some Managers would complain to HQS—you assigned me this job and JSC won’t cooperate. Not Charley Wood, he just kept writing!! Then JSC made a mistake—- they read 1 of his memos!! Or maybe 2 or more!! HEY!!!! This Guy knows what he’s talking about!!! Well SURPRISE!! SURPRISE!!! Charles Wood is one of the Most Intelligent NASA Employees! So, as in other areas, a Group was established: Propulsion Systems Integration Group ( P-SIG ) with members from MSFC, JSC, KSC, Stennis Space Center, Headquarters, and all involved Contractors. Charles Wood chaired the Group. So, the MSFC MPS Chief Engineers Office went from having memos Ignored, to where no one would even go to the Restroom without checking with Charley !!! Well, not really, but CLOSE!!

P-SIG was responsible for the testing at Stennis Space Center, Mississippi, of the MPTA—the Main Propulsion Test Article, which was an ET, Orbiter aft end, the 3 SSME’s, and a steel simulation of the Orbiter. Amazing that of about 16 static firings of the MPTA, before the 1st Shuttle flight, only 1 went for a full duration firing!!

No writing about Shuttle Propulsion would be complete without this: From the first Shuttle Launch, many wondered when a SSME would have a Significant Problem—because during its development there were Many !! Thankfully and a bit surprising, that never happened, and it is due to Incredible Talent & Dedication from many at MSFC, JSC, SSC, AND ROCKETDYNE!!

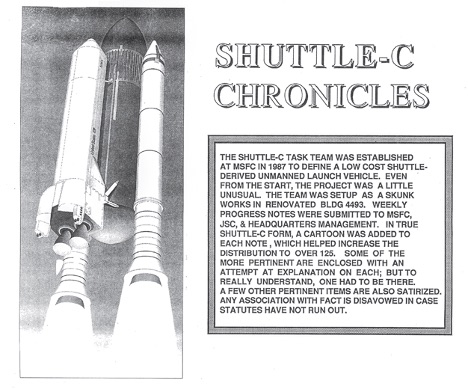

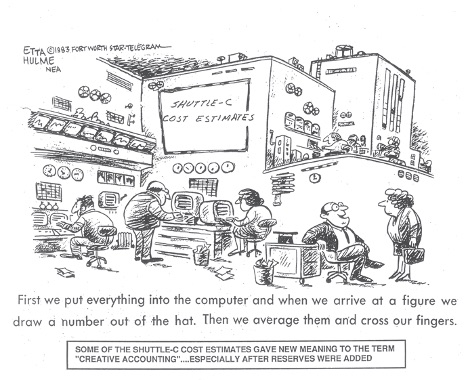

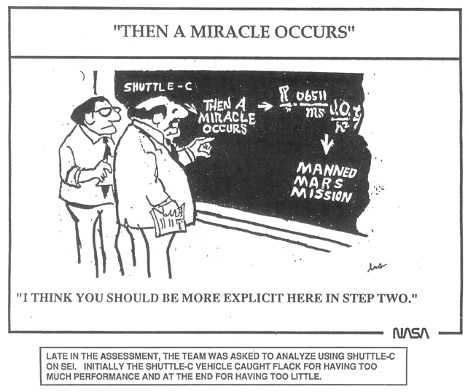

SHUTTLE-C TASK TEAM

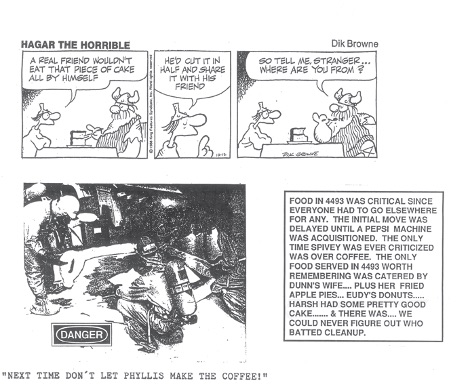

The SHUTTLE-C ( Cargo ) Task Team was established at MSFC IN 1987 to define a Low Cost Shuttle Derived Unmanned Launch Vehicle. The Team was setup as a “Skunk Works” in an old, small, former machine shop, renovated for human occupancy in 3 weeks —Building 4493. The Team varied from 11 to 16 personnel, and I was fortunate to be selected as the Test & Propulsion Guy. We were in Program Development, with Glenn Eudy as Project Manager & Bill Eoff as Deputy Manager. Study contracts were awarded to Martin Marietta Co., Michoud, LA; Rockwell, Downey, CA; & USBI, Huntsville. MSFC’s Program Development and S&E Directorates supported as needed. Weekly Progress Notes were submitted to MSFC, JSC, and Headquarters Managements. In true Shuttle-C form, a Cartoon was added to each note, which helped to increase the distribution to over 125!! Normal Weekly Notes distribution is usually 25-30!! Some of the more pertinent follow with an explanation on each. But to really understand, one had to be there!!

In May 1989, nearly 400 people participated in the SHUTTLE-C USERS CONFERENCE in HUNTSVILLE ! Team Member Terry Mitchell pulled a coup & got V P Dan Quayle to accept an invitation to be the Keynote Speaker !! However, a schedule conflict arose and J. R. Thompson delivered the Keynote Address.

SHUTTLE-C “enjoyed” quite a bit of Press Coverage— Michael Crichton wrote a POPULAR MECHANICS Magazine article, and a 7 minute Polished Video for Congressional & Coverage Release was produced by Restievo !! He said that the Video HAS to be 7 MINUTES MAX, to keep Congress’s attention !! The Title was : SHUTTLE- C: THE FUTURE IS NOW

However, despite all of this, SHUTTLE -C never flew or even reached Design. SHUTTLE-C could have delivered the INTERNATIONAL SPACE STATION Segments to orbit in a significant lesser number of Flights than the Shuttle ! Of course, being unmanned was a negative by some from the start.

After Shuttle-C, Bill Eoff was requested to spend a year at NASA Headquarters in Washington, D. C. He declined, stating I’ve already done my tour there ! So, before another position for Bill was found, he was left for 2 weeks in Bldg. 4493 —all alone!!! During this time, having nothing else to do, he originated and “published” the: SHUTTLE-C CHRONICLES, which was a 50 page ( front & back) unofficial document that contains a selected number of the Cartoons that were submitted with the SH-C weekly notes. Each cartoon has Bill’s attempt to explain! Following are 4 of them._

MISCELLANEOUS STORIES

ITS NOT A MICROWAVE OVEN, IT ONLY LOOKS LIKE ONE

During the early 1970’s, as post Apollo downsizing affected MSFC, the Test Area Cafeteria and Snack Bar were closed. That not withstanding, the NASA/MSFC Policy was to not purchase Microwave Ovens for employee use. Fully aware of this policy, but being a people oriented person, Jack Connor, Chief of Propulsion Test Division, decided that an exception should be made for the Test Area. After convincing Laboratory Management, he wrote an outstanding, very detailed justification stating that we were in a remote area and it was impossible to drive to the nearest Cafeteria, eat lunch, and return within 30 minutes. In addition, since many of our days, supporting the new Space Shuttle Program, ran far beyond the Cafeteria hours, Test Division employees needed and deserved a Microwave Oven.

The Procurement Office turned down the Purchase Order!

This incensed the Division Chief. Well, maybe incensed is too Harsh a word!! :-0)

However, being a persistent/intelligent/creative person, he changed the title of the Purchase Order from MICROWAVE OVEN to TRANSDUCER DRYER, kept the exact same Microwave Oven Specification, and changed the justification to a critical need ( Which was True ) to dry the microphones ( transducers ) that were used at TS-116’s Space Shuttle Acoustic Model Test Program.

The Purchase Order sailed through Procurement!!

And soon Test Division had for our Employees a Microwave Oven, which boosted morale considerably during the long working days—and nights!

Note: It was never used to dry any transducers/microphones as they all contained metal.

CARY REILLY & BILL HOLCOMB

Cary was an outstanding Test Engineer & Bill was an Outstanding Mechanical Technician. Together they were an exceptional Test Team & conducted a number of small component tests. Both had great sense of humor. So, for one Test, they needed some plexiglass—not much, about 1/2 of a sheet. They went to the Manufacturing Engineering Laboratory (ME Lab) where they should be able to “beg, borrow, or steal” some. M E Lab’s Building 4705 is a Huge High Bay building where the first Saturns were built, and had been converted to a Large Machine Shop. As they entered the building 4705, they spotted a number of sheets of plexiglass in a back corner of the building. They were immediately approached by 2 burly (as Cary described them) engineers, who blocked their way and stated that they had no plexiglass. As Cary and the engineers chatted, Bill wandered away leaving the engineers to chat among themselves. However, before Bill left, Cary heard him say, VERY QUIETLY:

“Keep ’em talking Reilly.”

That was No Problem for Cary, however, it was all he could do to keep from Laughing, as after a few minutes, Cary saw the back door open, and Bill entered & picked up a sheet of plexiglass & left!!!

Apparently, ME Lab never missed the sheet of plexiglass

MARSHALL’S BASKETBALL LEAGUES

There were 3 Leagues—Very Good, Good, & OK. I played mostly on the Test Lab Good Team, & some on the Very Good Test Lab Team. The Best MSFC Team was the Space Sciences Lab & they maintained that through the years as one of their player’s Dad was head of the Personnel Office!! For example, Bill Snoddy, a Supervisor in Space Sciences Lab, is at his desk studying, when he becomes aware of someone standing in front of his desk. He hears the words: “Mr. Snoddy?” & he looks up & right into the belt buckle of a guy who is 6’ 7” tall, or more!!

The guy says, I’m John XXX, your new CO-OP. Bill says, Welcome to Marshall, but I’m not expecting a CO-OP. John says, “You are today, Sir, The Personnel Office sent me!”

HUGGING OUR OLD MARSHALL TEST STANDS

In the 1990’s, when NASA, and especially MSFC, were struggling with the Future, the NASA Administrator said: “Those Marshall guys need to quit Hugging those Old Test Stands.” Of course, shortly thereafter, a number of us received a Very Nice “Certificate”!!! :-0)

CERTIFIED TEST STAND HUGGER

A TEST DIVISION PERK

Wandering around a remote area of one of our Buildings, an area I had never been in, and was not even close to the “Beaten Path”, I walked up a 1/2 flight of stairs. The first thing that I noticed was the Beautiful Hardwood Flooring, and next was a Barber Chair with its occupant being given a Haircut by 1 of our Technicians, with 2 guys waiting!!

I had No Idea that we had a Barber Shop!!!

Of course, I said NEXT !! and hung around a bit, and then told them that I have No Problem with a Barber Shop as I thought that it was a Good Morale Builder !! And I had just 1 Request—don’t let anyone Higher Up in Management than me, walk in on You like I just did.

GEORGE—THE TOUR GUIDE —AND A SHOT AT MOVIE “STARDOM”

I was assigned the responsibility for the many Tours through the Test Area. Especially having Very Knowledgeable Tour Guides. I couldn’t get many, if any, volunteers for Tour Guides, so I told Division Chief, Jack Connor, that I would do that. Being Deputy Division Chief, I should have time for them. I thoroughly enjoyed the role of Tour Guide !! The tours ranged from Space Camp 6th Graders to Admirals and Generals and those in between such as Congressional Staffers, ( 1/2 retirees, 1/2 recent graduates !! ) CEO’s, Teachers, Russians, the Director of the Japanese Space Agency ( He gave me a Necktie !! ) and ordinary folk!

Months before the filming of the Movie, “SPACE CAMP”, I conducted a tour of the Test Area for its Director and several others. They were looking at Facilities for possible use in the Movie. They all had LARGE IMAGINATIONS, and it was amazing to hear some of their “Wild Ideas”, like “Launching” a full size CARDBOARD Shuttle from the S-IC Test Stand!!! When the Film Crew moved into Huntsville, I went to their motel to try to sign up as an extra. Walking down the hallway, I saw a guy that I thought looked familiar. Amazingly, He, the Film Director, recognized me first as the “tour guy” and asked why I was there? I said that I was a Test Engineer and, as an extra, could sit at a launch console and look halfway intelligent. He immediately said, “ Oh no, I have a better part for you, Kathryn’s Dad.” I said, “What a coincidence, our Daughter is named Mary Kathryn!” So He took me past people waiting to audition, to sign some papers and read for the part !! My only line, as I deliver Kathryn to Space Camp, is ( with Great warmth!!! ) : “Have a Great Summer” I said that 3-4 times to each of 3 video cameras, and then went home to sit by the phone! Yeah Right!

Well, the guy who got “MY PART” looked somewhat like me, but spoke no words, probably Thanks to Me!!

And thus went my 1 shot at Movie Stardom!

MIKE PESSIN

A “Good Guy”

Highly Intelligent

Outstanding Supervisor

An Amazing Memory

Has a Cousin, Little PLACIDE, who, every day, tells Mike a Funny Story or a Joke that is usually off color a bit.

And Lucky Us, Mike passes them on!! 🙂

EPILOGUE

After Shuttle-C, I moved on to other “dreams” that never materialized such as: National Launch System, Advanced Launch System, Heavy Lift Launch Vehicle, and 1-2 others.

Then I ended my MSFC/NASA Career in the Space Shuttle Chief Engineers External Tank Office, with responsibility for the Main Propulsion System ( Marshall’s Rep to the P-SIG ) and was Chair of the Shuttle Projects Flight Evaluation Team ( The Team never had a Meeting !! ) there was no need—I coordinated, without Team meetings, each Project’s inputs and prepared the MSFC Shuttle Flight Evaluation Report for each Flight.

I could not have asked for a better ending!!

Author’s Footnote: SKYLAB MAN-RATED ALTITUDE CHAMBER AT MSFC Ref: Previous input, this Booklet, titled as above

This Program, I think, is VERY unique in the History of MSFC, not because it involved the testing of Humans— MSFC had other programs in that area, such as the Neutral Buoyancy Facility—but because of involving Test Subjects, AND the numerous and INTERESTING attempts by JSC To Cancel the Program at MSFC!!!

Therefore, if there is ANYTHING in this Test Program that in any way could have, or did, adversely affect the Safety of one or more Test Subjects, or adversely impacted the Test Program, the Competency, etc., etc. of MSFC to conduct these Tests would be challenged in every way possible!!! And that would include me! As follows.

In MSFC’s Test Laboratory, the TEST ENGINEER is Totally Responsible for EVERYTHING that happens in the Test Program—i. e. No matter who goofs, or what happens, or if the Test Stand explodes and burns to the ground, it’s on my ticket.

And that’s No Problem for me, or any Test Engineer.

And I never think about it, as that’s just the way it is!!

Also, I’ve never let that influence any decision that I’ve made—or didn’t make—or make me nervous.

I don’t think about things like that.

An example is when the Lt. Colonel came up from JSC to check us out as Man-Rated Chamber Operators. I did NOT get my Team together and give them a big pep talk, like: OK Guys, this is it, “sink or swim”, we’ll need our A-Game tomorrow. I don’t have an A-Game, or B-Game, etc. , etc. Rather, “I got Game”, as did my Team, as do all Test Lab Employees !! This is no Brag, just Fact.

So, the bottom line is that the Reputation of MSFC was on this Test Program’s and MY shoulders!!

And We came through!! —As Expected!!!

FYI: I got no pleasure from besting JSC. If that’s the right word ?

In fact I never really thought about it until writing this booklet!! I don’t get into Inter-Center, or Intra-Center, rivalries, and never view any situation as “them vs. us”! There is no “them”—ONLY US!!

DR. WERNHER VON BRAUN and THE APOLLO MOON PROGRAM

FOR DR. WERNHER VON BRAUN, THERE CAME IN HIS LIFE A SPECIAL MOMENT WHEN HE WAS TAPPED ON THE SHOULDER, AND OFFERED THE OPPORTUNITY TO DO A VERY SPECIAL THING, UNIQUE AND FITTED TO HIS TALENTS. WHAT A BLESSING FOR HIMSELF, FOR HIS FAMILY, FOR HIS FRIENDS, FOR HIS MSFC TEAM, FOR THOUSANDS OF NASA PERSONNEL AND CONTRACTORS, AND FOR HIS NATION, THAT THAT MOMENT FOUND HIM TOTALLY PREPARED AND EXCEPTIONALLY QUALIFIED FOR WHAT WOULD BE HIS FINEST HOUR!!! *

*Paraphrased from the Book: NO ROOM FOR ERROR by Colonel John T. Carney and Benjamin F. Schemmer